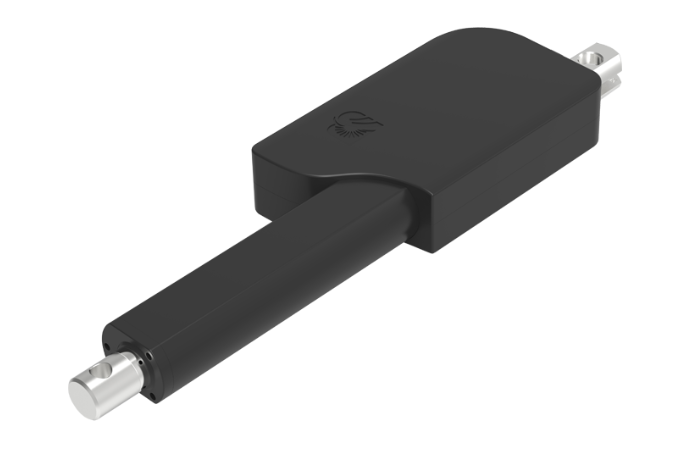

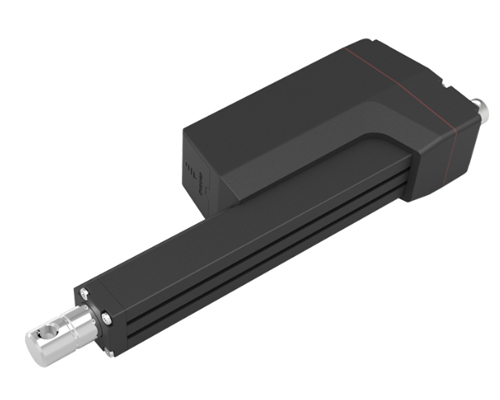

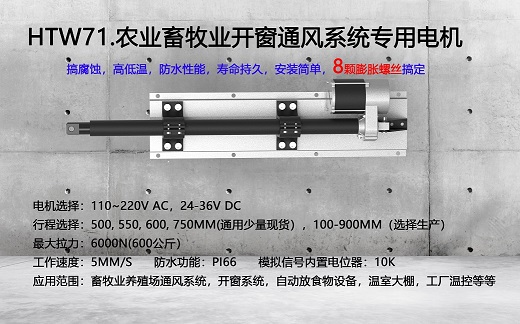

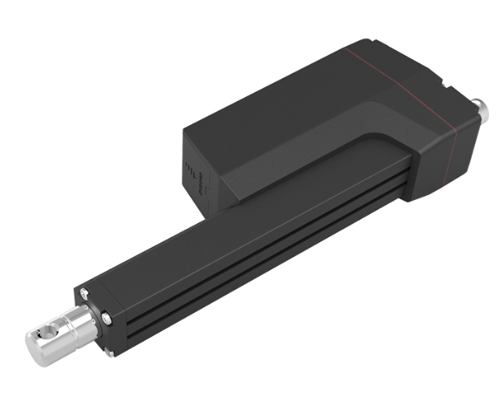

Self-locking electric cylinders, including servo motors, worm gear reducers, screw assemblies and anti-rotation mechanisms. The screw assembly includes a mating screw and a screw nut, and an end face of a lead screw nut is fixedly disposed with the linear actuator. The anti-rotation mechanism is prevented from rotating by two planes parallel to the outer surface of the linear actuator. The servo motor is connected to the one-way transmission through one end of the screw shaft through a worm gear reducer. The new transmission through the worm gear reducer utilizes the unidirectional self-locking characteristic of the worm gear drive to realize the mechanical self-locking of the electric cylinder, thereby eliminating the dependence on the electronic components and ensuring the reliability during operation; the output of the linear motion It is realized by the linear actuator, and the anti-rotation realized by the anti-rotation mechanism of the linear actuator realizes the linear motion of converting the nut into the rotary motion group, and the design is reasonable, the structure is ingenious, the work is stable, and the connection is compact.

Self-locking electric cylinders, including servo motors, worm gear reducers, screw assemblies and anti-rotation mechanisms. The screw assembly includes a mating screw and a screw nut, and an end face of a lead screw nut is fixedly disposed with the linear actuator. The anti-rotation mechanism is prevented from rotating by two planes parallel to the outer surface of the linear actuator. The servo motor is connected to the one-way transmission through one end of the screw shaft through a worm gear reducer. The new transmission through the worm gear reducer utilizes the unidirectional self-locking characteristic of the worm gear drive to realize the mechanical self-locking of the electric cylinder, thereby eliminating the dependence on the electronic components and ensuring the reliability during operation; the output of the linear motion It is realized by the linear actuator, and the anti-rotation realized by the anti-rotation mechanism of the linear actuator realizes the linear motion of converting the nut into the rotary motion group, and the design is reasonable, the structure is ingenious, the work is stable, and the connection is compact.-Self-locking electric cylinder

The new type belongs to the technical field of electric cylinders, especially electric cylinders with self-locking performance. The electric cylinder is a modular product designed by integrating a servo motor and a lead screw. It converts the rotary motion of the servo motor into linear motion. At the same time, the maximum advantage of precise speed control, precise speed control and precise torque control of servo motor is transformed into precise speed control, precise position control and precise thrust control. The new revolutionary realization of high precision linear motion series At present, electric cylinders have been widely used at home and abroad. Among them, the load and life of the electric cylinder have always been an important indicator of the electric cylinder. Self-locking, large-load, long-life electric cylinders are also widely used in many engineering applications. However, current electric cylinders use electronic self-locking in self-locking. In the event of an electrical failure, the electric cylinder loses its self-locking performance. At the same time, when the electric cylinder needs to be self-locking at the same time, large load and long life requirements. The structure of the electric cylinder is complicated, the volume is large, and the mechanical wear is more serious, which is not conducive to practical use.

Practical model content

The purpose of the utility model is to provide an electric cylinder with self-locking performance, which realizes self-locking by mechanical structure, stable operation and compact structure. It is realized by the following technical solutions: electric cylinder with self-locking performance, including: servo motor, worm gear reducer, screw assembly and anti-rotation mechanism; screw assembly including matching screws and nuts, end face of the lead screw nut and linear actuator Fixed settings. The anti-rotation mechanism is prevented from rotating by two planes parallel to the outer surface of the linear actuator. The servo motor is connected to the one-way transmission through a worm reducer through one end of the screw shaft.

A limit sensor placed on the cylinder of the electric cylinder.

In addition, the limit sensor is divided into three, which are used to test the zero position of the electric cylinder and the limit positions at both ends of the expansion and contraction.

In addition, the screw assembly further includes: a thrust ball bearing and an angular contact bearing installed at one end of the worm gear reducer; and a sliding bearing mounted at the other end. The thrust ball bearing and the angular contact bearing are matched with the lead screw, and the sliding bearing cooperates with the linear actuator.

Further, the lead screw is a ball screw.

In addition, the free end of the linear actuator is connected to the earring, and the outer side of the worm gear reducer is provided with a grounding anchor.

Compared with the prior art, the following beneficial technical effects are achieved: The new one-way self-locking characteristic of the worm gear realizes the mechanical self-locking of the electric cylinder. Driven by the drive connection of the worm gear reducer, eliminating the dependence on electrical components, ensuring and improving operational reliability. The output of the linear motion is realized by a linear actuator. The anti-rotation achieved by the anti-rotation mechanism of the linear actuator realizes the linear motion of converting the nut into a rotating motion group, and has a reasonable design, a clever structure and a compact connection.

In addition, the position of the electric cylinder can be accurately calculated by the setting of the limit sensor, and the safety and reliability are ensured during the operation; the radial load and the axial load of the angular contact bearing can be used to carry the screw. To meet the higher work requirements; the axial force of the spindle on the screw is endured by the thrust bearing, the load is large, and the space is small. The sliding bearing matched with the linear actuator is used to support the front end movement of the linear actuator, improve the smoothness of the working of the electric cylinder and reduce the volume; the mutual cooperation of the three bearings ensures the movement precision of the electric cylinder and reduces the movement precision. Wear and improve the service life and structural stability of the electric cylinder.

In addition, by providing a rolling screw, the friction between the screw assemblies can be better reduced, the overall rigidity of the screw assembly can be improved, and high-speed feed and micro feed can be achieved.

The locking electric cylinder includes a servo motor, a worm gear reducer, a screw assembly and an anti-rotation mechanism. The screw assembly includes a matching screw and a nut, and the end surface of the nut is fixedly pushed into the anti-rotation mechanism to prevent rotation by acting on two parallel planes with the outer surface of the linear actuator; the servo motor passes through the worm gear The reducer is connected to the one-way transmission through one end of the screw. Preferably, the limit sensor on the cylinder of the electric cylinder, the preferred embodiment uses three as an example of the limit sensor for testing the zero position of the electric cylinder and the limit positions at both ends of the expansion and contraction, respectively. When the electric cylinder reciprocates, when the nut 11 passes the limit sensor, the position of the electric cylinder can be calculated. Preferably, the lead screw assembly further includes a thrust ball bearing and an angular contact bearing mounted near one end of the worm gear reducer, and the sliding bearing is mounted at the other end. Thrust ball bearings and angular contact bearings are matched with lead screws, plain bearings and thrust. In a preferred embodiment, the lead screw is an example of a ball screw. The free end of the linear actuator is connected to the outside of the earring and the worm gear reducer for positioning and fixing the entire electric cylinder.

In use, the servo motor performs power input and is transmitted to the lead screw in the screw assembly through the unidirectional direction of the worm gear reducer, thereby driving the screw nut to generate a rotation tendency and preventing the anti-rotation mechanism from applying a thrust 对 to the wire. The lever nut rotates to convert the rotary motion into a linear motion that is output outward from the earring.

In the assembly example of the structure shown in the first embodiment, the linear actuator is first mounted on one end of the nut; then the angular contact bearing, the bearing retaining ring 7, the lower bearing seat, the thrust roller bearing, the round nut and the round nut are mounted on the screw The rear end, and the angular contact bearing and the thrust roller bearing are positioned by the lower bearing seat and the round nut, and the round nut realizes position locking. Then install the cylinder on the lower housing and use the screws. Locking and positioning; the anti-rotation mechanism and the sliding bearing are sequentially mounted on the upper bearing seat, the upper bearing seat is mounted on the free end of the cylinder body, and is positioned by screws, and the sealing ring and the upper cover are sequentially mounted on the upper bearing seat; The round nut and earrings 17 are mounted on a linear actuator and are positioned and locked with a round nut; the key is mounted on the lead screw to connect the output of the remaining worm gear reducer; the lower cover and the worm gear reducer are mounted in the lower bearing in sequence The seat is locked and positioned with screws; the ground anchor I and the servo motor are respectively mounted on the worm gear reducer, and the limit sensor is mounted on the cylinder block.

Self-locking electric cylinders include: servo motor, worm gear reducer, screw assembly and anti-rotation mechanism; the screw assembly includes matching screws and nuts, and the end face of the nut is fixed with a linear actuator. The outer surface of the rotating mechanism and the linear actuator are prevented from rotating in two parallel planes. The servo motor passes through a worm gear reducer and a one-way transmission. Connect to one end of the lead screw. A self-locking electric cylinder according to claim 1, further comprising a limit sensor disposed on a cylinder of said electric cylinder. The self-locking electric cylinder according to claim 1 or 2, wherein the limit sensor is divided into three, and is used for the zero position of the electric cylinder and the limit of the two ends when being extended and contracted. carry out testing.

The self-locking electric cylinder according to claim 1, wherein the lead screw assembly further comprises a thrust ball bearing and an angular contact bearing, and the thrust ball bearing and the angular contact bearing are mounted at an end of the worm gear reducer. Near the portion, and the other end is mounted on the sliding bearing. End; the thrust ball bearing and the angular contact bearing cooperate with the lead screw, and the sliding bearing cooperates with the linear actuator.

The self-locking electric cylinder according to claim 4, wherein the lead screw is a ball screw.

A self-locking electric cylinder according to any one of the preceding claims, wherein a free end of said linear actuator is coupled to said earring, said worm gear reducer being provided with a ground anchor.

Product

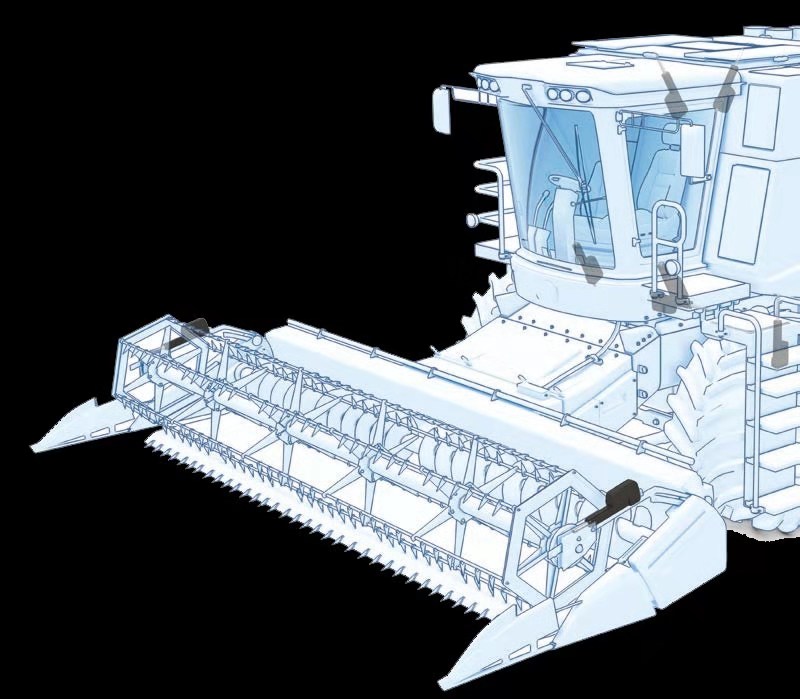

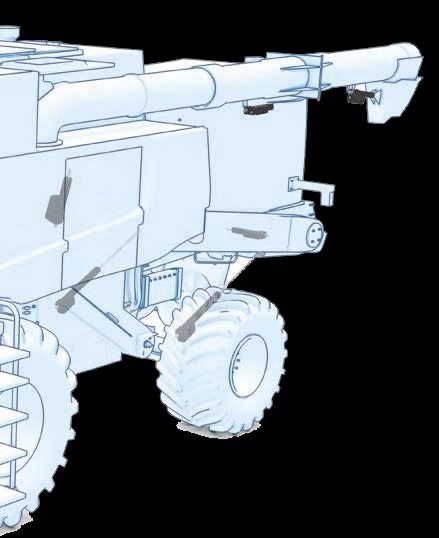

Product Industrial Use

Industrial Use Furniture & medical Use

Furniture & medical Use PV Drive

PV Drive Collaborative Robots

Collaborative Robots Technical Support

Technical Support About us

About us Culture

Culture Milestone

Milestone Responsibility

Responsibility Contact Us

Contact Us News and Events

News and Events Global agents

Global agents Certificate

Certificate GeMinG

GeMinG English

English